7 Things You Didn’t Know About Golf Balls

Golf balls have certainly come a long way since their 14th century beginnings as lopsided pieces of wood. The 17th century saw particularly incredible innovation, when the sport’s enthusiasts stuffed pouches with dense wads of wet leather to create a hard core, then added feathers that dried into a denser outer layer. Today’s golf balls are virtually unrecognizable in comparison and, let’s face it, infinitely better.

Golf balls must address the golfer’s every need, providing distance on drives, spin and trajectory on the approach, and control on the green. Balls try to solve for a lot of factors and objectives to optimize its performance on any shot the golfer can imagine, making its construction a key factor. Here are seven things you probably don’t know about golf balls.

1. A golf ball can’t weigh more than 1.62 ounces (or 45.93 grams).

Modern golf balls are made from a range of materials and methods, but to be recognized in tournament play, they can’t weigh more than a mere 1.62 ounces or 45.93 grams. Taken together, the elements of a ball’s design and construction have a profound impact on its overall performance on the course. The golf ball is perhaps the most important piece of equipment in the golfer’s bag—it’s the only piece of equipment that golfers use on every single shot.

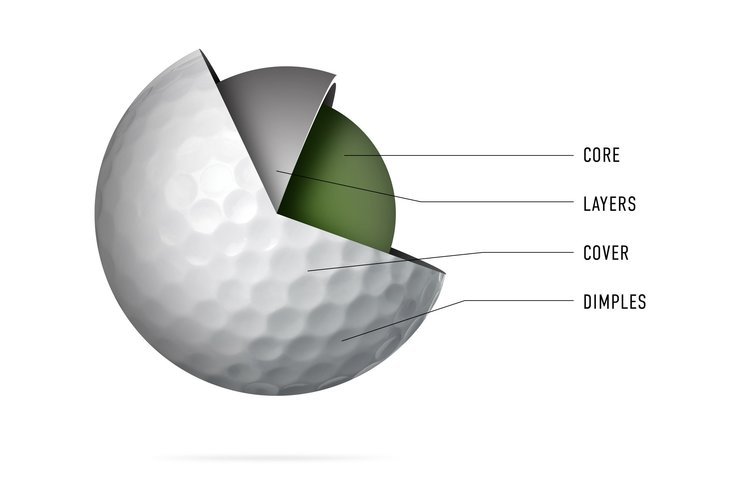

2. Golf balls are made of layers.

At its most basic level, a golf ball includes an inner core made from pressurized rubber or synthetic rubber, surrounded by one or several outer layers, and a characteristically dimpled cover. Each of its collective elements contribute to its performance on a shot, and even subtle changes to one or more elements can make a drastic impact. Their construction increases the ball’s spin that lends itself to greater control, especially in the short game.

3. The core is crucial.

The core is often considered the ball’s engine, influencing not only its speed and distance, but its spin in the long and short game. The force used to strike the ball is transferred directly into the injection-molded rubber that is a ball’s core, where it is stored and released to propel the ball forward. For this reason, the core is often considered the ball’s engine, influencing not only its speed and distance, but its spin in the long and short game. In multi-layer construction, where another layer is positioned between the ball’s core and its cover, the inside layer is made of rubber thread compressed to varying densities.

4. A golf ball’s compression is a factor in speed and spin.

The ball’s compression is a reflection of how hard or soft the ball compresses against the club face when hit. While the influence of compression is a hotly debated topic among golf experts and equipment manufacturers, the general consensus is that a harder ball (with a higher numerical compression) compresses less on the hit, while a softer ball compresses more. Golfers with a faster swing speed are typically more apt to prefer a harder ball, but it’s more of a matter of personal preference for feel. Compression has an impact on general performance. For example, as a broad rule, if you have two golf balls that are identical with the exception compression, the higher compression ball will have more speed and more spin across the entire range of shots while the lower compression ball will have lower speed and lower spin. That being said, this relationship is not universally true. Some higher compression golf balls have lower speed and spin because of other components of their design.

5. The cover impacts the feel and the ball’s spin off of the club head.

The exterior surface of the golf ball is referred to as its cover and is constructed either of Surlyn (a thin, plastic resin created and trademarked by DuPont) or urethane (a slightly softer, slightly less durable synthetic compound). All else being equal, Surlyn can contribute to distance, but tends to inhibit spin. Urethane covers, while typically more expensive, have a tendency to deliver higher spin rates off irons and wedges, providing more control in the short game. For golf ball manufacturers, the cover is another crucial opportunity for innovation that impacts its overall performance.

6. The ball’s dimples have a purpose.

The dimples on the surface of the golf ball play a surprisingly complex role in its flight, speed, lift, and spin. Compared to a smooth ball, the small indentations make golf balls more aerodynamic, manipulating the airflow around the ball to create a tighter vortex that effectively decreases the ball’s drag and increases its distance, speed, and lift. Like the other design and construction components, these dimples can be manipulated by manufacturers that increase and decrease their size, quantity, and pattern to impact the speed, flight, spin, and overall performance of the ball. They’re also an important consideration when it comes to weather and other playing conditions to provide consistency in how a golf ball performs in all types of conditions.

7. Manufacturers are always innovating.

Given the leaps and bounds of innovation across golf ball construction, materials, and performance over the last several decades, the industry’s focus on research and development should come as no surprise. Most manufacturers look toward TOUR players for feedback on prototyped and developing products, but investments in innovation run far deeper, including divisions and teams of engineers, technicians, chemists, aerodynamicists, and other scientists. R&D teams spend time working with golfers to understand their performance needs. With every innovation, consistency remains central, given the slightest deviation in quality can have a dramatic impact on a golfer’s game. It’s especially important for amateur golfers, who have a tendency to assume a flaw in their swing when they hit the ball the way they wanted to hit it, but it doesn’t perform as expected.

Final Thoughts

In all, the right ball is unique to each individual golfer’s goals and preferences. Still, the surprisingly complex science behind the sport’s central component plays into every piece of a golfer’s game—from the way it feels off the tee to the moment it hits the cup. The golf ball is an important equipment decision that makes a huge difference for golfers at all skill levels—perhaps the most important of all.